Why Solar Farm Preparation Is the Foundation of Every Successful Project

Solar farm preparation is the critical first phase that transforms raw land into a construction-ready site for renewable energy generation. It is a complex, multi-stage process involving a sequence of essential steps—from initial feasibility studies and land clearing to precision grading and utility infrastructure development—that must be meticulously executed before a single solar panel is installed.

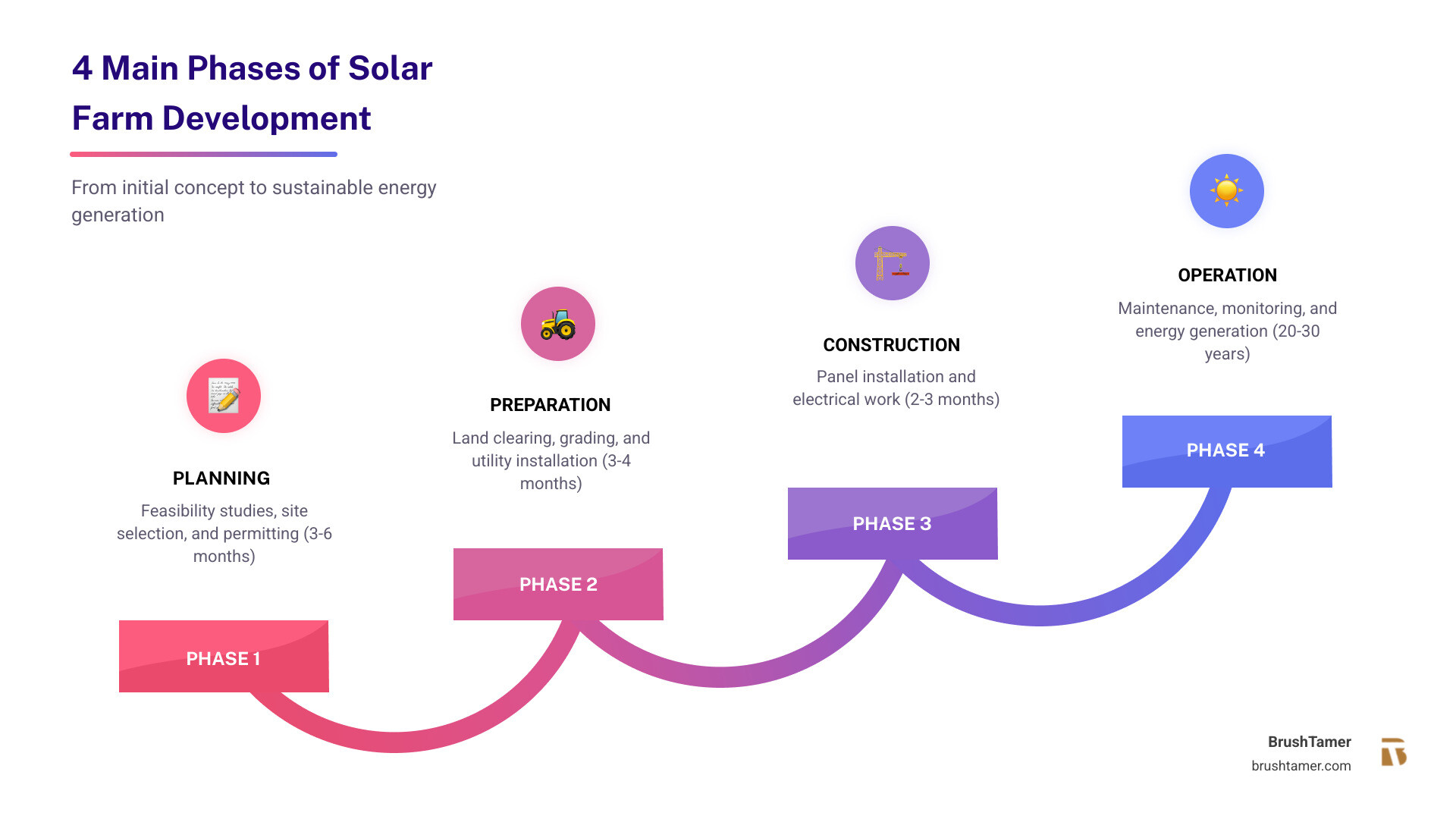

The four key stages of solar farm development are:

- Site Planning & Assessment: In-depth feasibility studies, geotechnical analysis, and navigating complex regulatory reviews.

- Land Clearing & Vegetation Management: Systematically removing trees, brush, and other obstacles to prepare the canvas for construction.

- Grading & Infrastructure: Leveling the terrain to precise specifications, building durable access roads, and installing critical drainage systems.

- Utility Installation: Trenching for electrical conduits and preparing the site for grid interconnection.

The stakes are incredibly high. Industry research reveals that approximately 80% of solar projects fail before reaching the construction phase. These failures are rarely due to a lack of funding or ambition; they are most often the result of inadequate planning and preparation. Unforeseen soil conditions, insurmountable regulatory hurdles, or poor site layouts discovered too late can derail a project, wasting millions in development capital. The difference between a successful, revenue-generating solar farm and an abandoned project frequently comes down to the thoroughness of this foundational groundwork.

As the U.S. aims to double its annual solar installation rate by 2030, fueled by initiatives like the Inflation Reduction Act, the demand for expertly prepared sites is soaring. A utility-scale solar farm is a massive undertaking, and the preparation phase is an intensive effort that sets the stage for everything to follow. Proper site preparation isn’t just a preliminary step—it’s the strategic investment that de-risks the entire venture and determines its long-term success.

I’m Leon Miller, owner of BrushTamer. With years of experience in complex land clearing projects across Indiana, we’ve seen firsthand how the principles of professional solar farm preparation—careful planning, environmental stewardship, and efficient execution—are essential for turning renewable energy goals into reality.

The Blueprint for Success: Project Planning and Site Selection

Every successful solar farm begins with meticulous planning and site selection, a foundational phase that separates thriving projects from those that fail before construction. This stage starts with a comprehensive feasibility study to analyze land availability, solar resource potential, grid connection options, environmental impacts, and project economics. This deep-dive assessment reveals what the land needs before solar farm preparation can begin. Key components of this study include:

- Solar Irradiance Analysis: Using data from sources like the National Renewable Energy Laboratory (NREL), developers model the site-specific Global Horizontal Irradiance (GHI) and Direct Normal Irradiance (DNI) to accurately forecast energy production and revenue.

- Geotechnical Investigation: Soil borings are taken across the site to determine soil composition, load-bearing capacity, and depth to bedrock. This data is crucial for designing the panel foundations (piles) and avoiding costly surprises during construction.

- Hydrological and Topographical Surveys: Detailed surveys map the site’s slopes, drainage patterns, and identify any floodplains. This is essential for planning grading, stormwater management systems, and ensuring the long-term stability of the site.

Site selection is arguably the most critical decision. While an ideal site is relatively flat with minimal vegetation, such land is rare. Understanding topography is crucial for transforming challenging terrain into a productive solar site. Our experience in Professional Land Management proves that proper planning can overcome these obstacles. A key factor is proximity to infrastructure; developers prefer sites within two miles of a substation and close to transmission lines, known as Points of Interconnection (POIs), to minimize the high cost of running new lines. The entire process is typically managed by Engineering, Procurement, and Construction (EPC) companies, who act as the prime contractor and hire specialists like us for site preparation.

Navigating the Regulatory Maze: Permitting and Approvals

Before breaking ground, developers must navigate a complex web of permits from local, state, and federal agencies. This process, overseen by the authority having jurisdiction (AHJ), can be lengthy and includes land use, zoning, grading, and construction permits. Environmental permits are often the most complex, sometimes requiring a full Environmental Impact Assessment (EIA) under the National Environmental Policy Act (NEPA). Key federal regulations include Section 404 of the Clean Water Act, which governs activities in wetlands, and the Endangered Species Act, which protects critical habitats. In the Midwest, developers must minimize core forest impact and respect wetland buffers, which can require setbacks of up to 100 feet. Following guidelines like the Conservation Guidance for Utility-Scale Solar Projects is essential for ensuring compliance and maintaining the long-term health of the land.

The Rise of Agrivoltaics: Dual-Use Land Strategies

An innovative approach changing solar development is agrivoltaics, which combines solar energy generation with agriculture on the same land. Solar panels are installed at a height that allows farming activities to continue underneath. This dual-use strategy offers farmers new revenue from land lease payments without abandoning agriculture. The partial shade from panels can reduce water needs and protect crops like leafy greens, herbs, and peppers from extreme heat. Sheep grazing has become a popular, natural method for vegetation management, reducing maintenance costs and improving soil health. For developers, agrivoltaic sites are often easier to acquire and can benefit from the cooler microclimates created by the vegetation, which can slightly improve panel efficiency. Resources like the AgriSolar Clearinghouse provide guidance for those interested in this sustainable model, which aligns perfectly with our Vegetation Management Solutions.

Breaking Ground: The Core Stages of Solar Farm Preparation

Once planning and permitting are complete, solar farm preparation moves from paperwork to groundwork. This is where raw land is physically transformed into a construction-ready site, a process that can take several months of intensive work. For a utility-scale project, this means preparing hundreds of acres—clearing, leveling, and equipping the land with the necessary infrastructure for decades of reliable operation.

This core work breaks down into three interconnected stages, where quality work early on makes everything that follows more efficient and cost-effective.

Stage 1: Professional Land Clearing and Vegetation Management

The first physical step in solar farm preparation is clearing trees, brush, stumps, and invasive species. At BrushTamer, our Environmentally Friendly Land Clearing approach uses modern forestry mulching. Instead of traditional methods that involve uprooting stumps (grubbing) and hauling debris to a landfill, our horizontal grinders and whole tree chippers process vegetation on-site. This turns it into valuable mulch that can be spread between solar panel rows to suppress weeds, retain soil moisture, and prevent erosion—a sustainable solution that reduces long-term maintenance. This method also minimizes soil disturbance, protecting topsoil and reducing the risk of erosion. Our Industrial Vegetation Management fleet is equipped to handle any terrain, leaving the site clean and ready for grading.

Stage 2: Grading, Access, and Essential Groundwork

With vegetation cleared, the earthwork begins. This stage of solar farm preparation reshapes the land to ensure proper water drainage and create a surface suitable for the racking system. While perfectly flat terrain isn’t required, strategic grading creates a uniform surface, often with tolerances of just a few inches, to allow for efficient installation of modern tracking systems. A critical, often underestimated, task is building stable access roads. These roads must support heavy construction equipment and provide reliable maintenance access for 25-30 years in all weather conditions. We also focus on implementing a robust Stormwater Pollution Prevention Plan (SWPPP), designing and installing drainage systems like retention basins, bioswales, and silt fences. Our Erosion Control Services protect the site and local water quality, preventing costly fines and remediation work down the road. For context on the investment, our guide on the Cost to Clear and Level 1 Acre of Land provides a helpful baseline.

Stage 3: Powering Up with Utility and Electrical Installation

The final preparatory stage establishes the electrical infrastructure connecting the farm to the grid. This specialized work involves installing an underground network of conduits for DC collection and medium-voltage AC lines. Proximity to a substation is key, as determined in the planning phase. Contractors use trenching with a utility tractor for open areas or, for crossing obstacles like roads or wetlands, horizontal directional drilling (HDD). This phase also includes pouring concrete pads for inverters and transformers and preparing the main switchgear area. The cleared and graded site we prepare provides the stable, accessible surface electrical crews need to work efficiently, laying the final piece of the foundation for a successful project.

From Piles to Panels: The Construction Phase

With solar farm preparation complete, the project moves into the construction phase. This is where the cleared, graded, and utility-ready site becomes a tangible, energy-producing asset. This phase transforms months of planning into a functioning power plant in a matter of months.

The construction sequence is a logical progression that relies on the quality of the site prep. It begins with pile driving, where specialized machines pound thousands of steel piles (such as I-beams or helical piles, depending on soil conditions) into the ground to create the foundation. Next, crews assemble racking systems onto the piles. These can be cost-effective fixed-tilt systems or, more commonly, single-axis tracking systems that follow the sun from east to west, increasing energy yield by up to 25%.

With the racking in place, solar panel installation begins. Workers mount each panel, ensuring proper alignment to withstand decades of Midwest weather. The final step is making all electrical connections, wiring panels to inverters and linking the system to the grid infrastructure. The entire farm then undergoes rigorous testing and commissioning before it can be declared commercially operational. This includes IV curve tracing to verify panel performance, insulation resistance testing for safety, and thermal imaging scans to detect any faulty connections or ‘hot spots’.

The Right Tools for the Job: Key Construction Equipment

This transformation requires an array of specialized machinery. Pile drivers are essential for creating the foundation with speed and precision. Cranes and telehandlers handle the heavy lifting of transformers and racking components. Forklifts and versatile skid steers move materials like panel pallets and mulch around the site. For the electrical work, trenchers and horizontal directional drilling (HDD) rigs are used for the crucial underground work that connects the farm to the grid. The efficiency of all these machines depends directly on the stable, accessible site created during the solar farm preparation phase, which is central to our work in Solar Power Development.

Overcoming Problems and Leveraging Expertise

Even with meticulous planning, large-scale solar projects face inevitable challenges. The high project attrition rate before construction is a testament to how easily things can go wrong, from permitting delays and grid capacity issues to unforeseen terrain and supply chain disruptions. In the Midwest, a week of heavy rain can halt progress entirely.

However, every challenge is an opportunity for experienced contractors to prove their value. The key to success is anticipating problems and solving them proactively. At BrushTamer, our experience managing complex land projects has taught us that strategic thinking is as important as moving dirt.

Common Challenges in Solar Farm Preparation and How to Solve Them

- Environmental & Regulatory Problems: Navigating a maze of federal, state, and local laws regarding wetlands, endangered species, and water quality is a primary challenge. The solution is conducting thorough environmental reviews early and designing site plans that work with the land, not against it.

- Unforeseen Site Conditions: Bedrock just below the surface or unstable soils can derail a project. Comprehensive geotechnical studies during the feasibility phase reveal these issues when they can still be addressed through planning, not crisis management.

- Grid Interconnection Delays: A local grid may lack the capacity to handle a new solar farm’s output. Projects enter a long “interconnection queue” to wait for utility studies that determine necessary grid upgrades, which can take years and add millions in unexpected costs. The solution is early and transparent engagement with utility companies to understand these constraints from the outset.

- Supply Chain Volatility: The global supply chain for solar panels, transformers, and switchgear can be unpredictable. Proactive procurement strategies, vendor diversification, and flexible construction schedules are essential to mitigate delays.

- Weather Delays: A fact of life in the Midwest, weather can be managed with smart scheduling, contingency buffers, and flexible crews. Our Vegetation Management Solutions are designed for efficiency in various conditions to minimize downtime.

Transitioning to Solar: Opportunities for Construction Companies

The solar boom offers a significant opportunity for construction companies to diversify. Skills from industries like oil and gas pipeline construction and utility work are directly transferable to solar farm development. The same expertise in land clearing, grading, and trenching is required. For companies like BrushTamer, specializing in solar farm preparation is a natural extension of our core services. The key is partnering with EPC companies that need reliable subcontractors who understand the unique demands of solar sites and can deliver consistent quality, ensuring the project’s foundation is solid.

Frequently Asked Questions about Solar Farm Preparation

We’ve had countless conversations about the nuts and bolts of solar farm preparation. Here are answers to the most common questions we hear at BrushTamer.

How much land is needed for a solar farm?

The general rule of thumb is approximately five to seven acres of buildable land for every megawatt (MW) of capacity. The exact acreage varies based on panel technology (more efficient panels require less space), racking systems (trackers need more room than fixed-tilt), terrain, and environmental setbacks. For community solar projects common in the Midwest, you’re typically looking at 10 to 50 acres. The key is not just total acreage, but usable, accessible land that can support the project’s infrastructure.

What is the role of an EPC company?

EPC stands for Engineering, Procurement, and Construction. These companies act as the prime contractor or “quarterback” for a solar project, overseeing it from design to completion. They engineer the optimal layout, procure all materials and equipment (panels, inverters, racking), and manage the entire construction phase. EPCs hire specialized subcontractors for specific tasks, which is where companies like BrushTamer come in. We partner with EPCs to handle the critical solar farm preparation phase, providing expert land clearing, grading, and vegetation management services.

How long does the entire solar farm development process take?

For a well-managed project, the entire process from initial concept to a fully operational solar farm typically takes twelve to twenty-four months, though it can be longer. This timeline can be broken down into key phases:

- Development, Planning, & Permitting (6-12+ months): This initial phase involves site selection, feasibility studies, securing land rights, navigating the grid interconnection process, obtaining all permits, and finalizing the engineering design. It is often the longest and most unpredictable phase.

- Procurement & Site Preparation (4-6 months): Solar panels and major equipment are ordered. Simultaneously, the site preparation work of clearing, grading, and road building takes place.

- Construction & Commissioning (3-6 months): This includes the physical pile driving, racking, panel installation, electrical work, and final testing before the farm goes live.

What are the long-term site maintenance needs after preparation?

While the initial preparation is a one-time effort, the site itself requires ongoing maintenance for its 20-30 year lifespan. This includes vegetation management (regular mowing, targeted herbicide application, or managed grazing to prevent shading and fire risk), erosion control (inspecting and repairing swales, culverts, and slopes, especially after major storms), and access road upkeep (grading and adding gravel as needed to ensure year-round access for maintenance crews). Proper initial preparation significantly reduces the cost and effort of this long-term upkeep.

Conclusion: Your Partner in Powering the Future

The journey through solar farm preparation reveals a fundamental truth: a project’s success hinges on the quality of its foundation. This is not merely about moving dirt; it is a multi-disciplinary science that blends geotechnical engineering, hydrology, environmental compliance, and logistical precision. Thorough planning, professional land clearing, and precise grading are what prevent a project from joining the 80% that fail before breaking ground. The difference between a high-performing asset and a costly write-off is preparation done right.

At BrushTamer, we’ve built our reputation on understanding that land is the canvas for the future of renewable energy. Our experience across Indiana, Michigan, Ohio, Illinois, and Wisconsin has taught us there are no shortcuts to quality. Every acre we prepare is handled with the commitment to excellence that has made us a trusted partner for solar developers and EPC companies throughout the Midwest.

The renewable energy sector is accelerating, and meeting future goals requires the practical expertise to turn vision into reality. The path to a successful solar farm begins with a partner who understands the technical demands and environmental responsibilities of solar farm preparation. We do it right the first time, delivering a de-risked, construction-ready site that stands the test of time.

For expert land clearing and solar farm site preparation, contact Brush Tamer today!