More Than Just a Piece of Steel

Plow disc equipment is the backbone of effective soil preparation, a critical evolution from the traditional moldboard plows of the past. Where older plows simply turned soil over, the modern disc harrow offers versatile solutions for breaking ground, managing dense crop residue, and carefully preparing seedbeds. Whether you’re looking for smooth discs for fine tillage work, notched discs for aggressive cutting through tough conditions, or complete disc harrow systems, the right equipment can fundamentally transform your land management approach from a chore into a science.

This isn’t just a tool; it’s a system. Understanding the components is key to open uping its potential.

Key Plow Disc Options:

- Smooth discs – The artist’s brush of tillage. Best for general soil working and creating a fine, level finish ideal for planting.

- Notched discs – The workhorse for tough jobs. Ideal for penetrating hard ground, chopping through heavy corn stalks or other residue, and breaking new ground.

- Tandem disc harrows – A marvel of engineering that uses opposing gangs of discs to create balanced forces, allowing for straight towing and uniform soil mixing.

- Offset disc harrows – The heavy-hitter for primary tillage, designed to move massive amounts of soil and residue when breaking new ground or revitalizing neglected fields.

- Individual replacement blades – The essential components for maintenance, with a wide range of 16″ to 28″ diameter options available to fit nearly any implement.

The global disc harrow market, valued at $1.2 billion in 2022 and projected to grow, reflects the critical role these tools play in modern agriculture and land management. This growth is driven by the need for more efficient farming practices (conservation tillage), the development of more durable materials like boron steel, and the reclamation of land for new uses. Disc plows are designed to work in all types of soil for functions such as soil breaking, soil raising, soil turning, and soil mixing, making them especially valuable in rocky and rooted areas where other equipment would fail or sustain heavy damage.

From small 4-foot units perfect for creating wildlife food plots with an ATV to massive 25-foot hydraulic-folding systems for commercial farming operations, plow discs handle everything from light stubble management to the arduous task of breaking new ground. They excel in conditions where traditional moldboard plows fail, such as rocky and rooted areas and hard and dry trashy land conditions where scouring is a major problem.

I’m Leon Miller, owner of BrushTamer. For over two decades, I’ve been on the ground, using every configuration of plow disc imaginable. My work isn’t just about clearing brush or mulching forests; it’s about what comes next. It’s about preparing the land for its new purpose. This hands-on experience has taught me one thing above all: the right disc selection isn’t just a choice, it’s an investment that can make or break the success of any land management project.

Types of Plow Discs and Their Applications

The world of plow discs is far more diverse and nuanced than many realize. Each type is carefully engineered for specific soil conditions, residue levels, and farming challenges. After years of working with countless disc configurations across the varied soils of the Midwest, from the heavy clays near Lake Michigan to the sandy loams of central Indiana, I’ve learned that choosing the right type is the difference between a smooth, efficient operation and a frustrating, fuel-guzzling day in the field.

Smooth vs. Notched Discs: What’s the Difference?

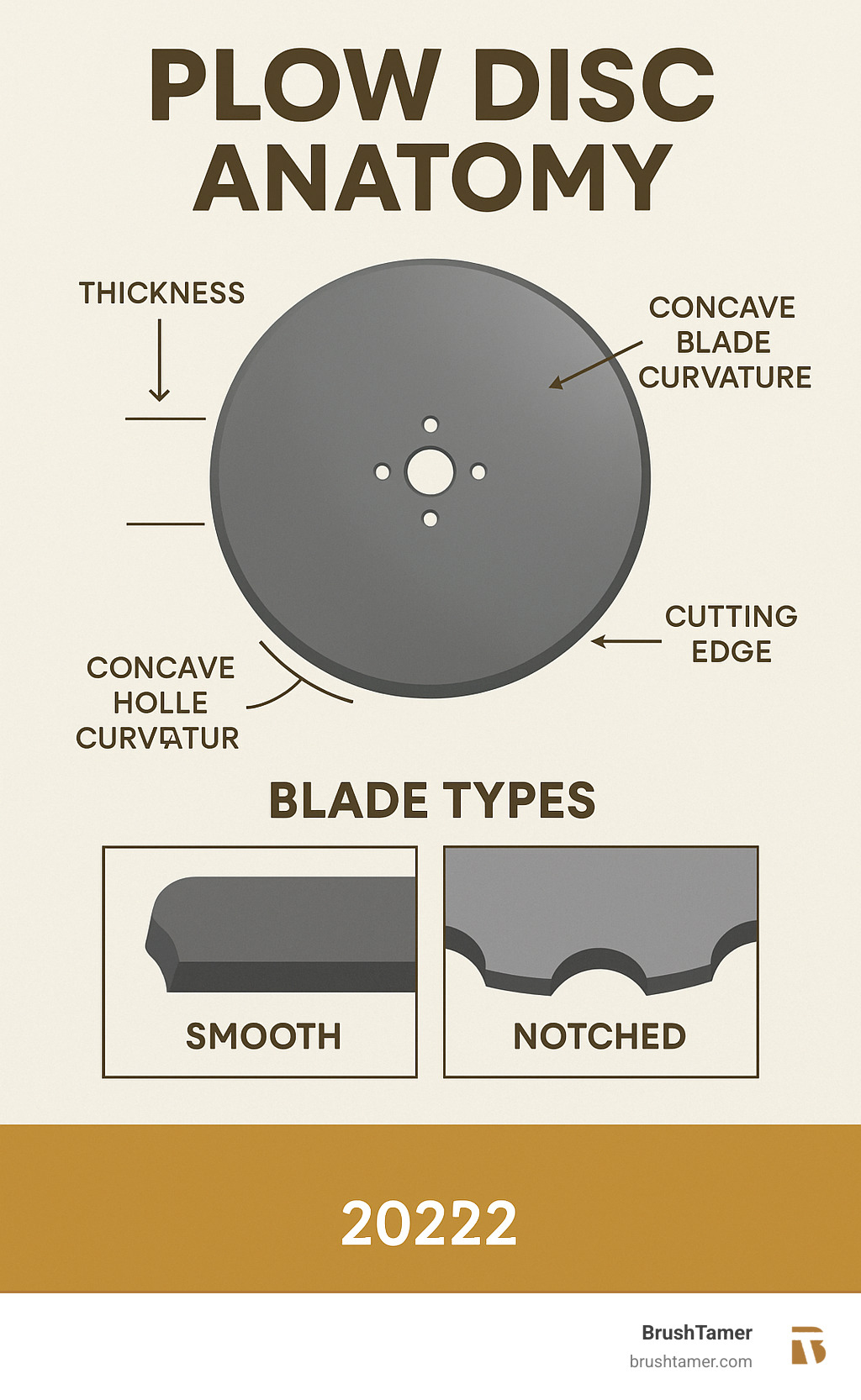

When you’re staring at a plow disc, the most obvious feature is its edge: is it a continuous, smooth circle or does it have distinctive notches? This isn’t a cosmetic choice—it fundamentally dictates how the disc interacts with soil and residue.

Smooth discs are the workhorses of secondary tillage and finishing. Their continuous cutting edge slices cleanly and uniformly through the soil, creating that fine, pulverized soil finish that’s perfect for an ideal seedbed. Think of them as the precision tools of the disc world. When I’m working on land that’s already been cultivated or has light residue, like after a soybean harvest, smooth discs give me the clean, level, and consistent results that clients expect for planting. They excel at breaking down smaller clods and leveling the field for subsequent passes.

Notched discs, often called cutout discs, are the aggressive cousins in the family. Those jagged edges, or notches, aren’t for show—they’re designed for maximum cutting power and residue flow. When you’re facing hard, unworked ground, or dealing with heavy, tough crop residue like corn stalks or sorghum stubble that would clog up smooth discs, the notched edges provide a powerful gripping and slicing action. They chop through the trash, prevent hairpinning (where residue is pushed into the seed furrow instead of being cut), and bite into compacted soil. I’ve seen these discs power through conditions that would bring other equipment to a dead stop.

There’s also a third, less common category: scalloped discs. These offer a middle ground, with wavy edges that provide more cutting action than a smooth disc but a finer finish than a notched one. They are a good compromise for all-purpose use in moderate conditions.

Understanding Disc Curvature, Angle, and Design

The shape, angle, and arrangement of your plow disc system determine how it moves soil, how much residue it buries, and how much horsepower you’ll need to pull it. Getting this right can save you significant amounts of fuel, time, and mechanical wear.

Concave discs are curved inward like a shallow bowl. This curvature, or concavity, is what gives them their soil-moving magic. They don’t just slice; they lift, turn, and mix the soil. The deeper the concavity, the more aggressively the soil is inverted. This design is what makes disc plows so effective for deep tillage and incorporating organic matter. The angle of the disc gang relative to the direction of travel is also critical. A more aggressive angle (more perpendicular to the direction of travel) results in more soil being moved and a rougher finish, while a shallower angle provides a smoother finish and requires less power.

Tandem disc harrows are beautifully balanced machines. They use two or four sets of disc gangs working in opposition. The front gangs are typically set to throw soil outward, while the rear gangs are set to pull it back inward. This creates balanced forces that keep the implement tracking straight behind the tractor, making it easier to control and producing a remarkably uniform finish. This is my go-to setup for creating a perfect seedbed across a large field, as it ensures any follow-up work like planting or spraying is much smoother.

Offset disc harrows take a different, more aggressive approach. Their gangs are positioned in an offset pattern, not directly behind one another. This design allows for tremendous soil-moving power and deeper penetration. These are the heavy hitters I turn to for primary tillage, especially when breaking new ground, clearing pasture, or working in extremely challenging, high-residue conditions. They can handle massive volumes of soil and trash that would overwhelm lighter tandem harrows.

The Right Plow Disc for the Job

Matching your plow disc to your specific task is where experience really pays off. Over the years working across territories from South Bend, Indiana, to Chicago, Illinois, I’ve learned that the right tool for the job makes all the difference.

For farming applications, plow discs are masters of seedbed preparation. They break down clods, create a fine, uniform texture for optimal seed-to-soil contact, and promote germination. They are also fantastic for mechanical weed control, efficiently cutting and burying weeds before they can establish. In conservation tillage systems, they are used to manage residue levels, while in conventional systems, they follow a primary plow to finish the field.

When breaking new ground, you need serious cutting and chopping power. Heavy-duty offset discs with large-diameter, thick, notched blades are the tool of choice. They can slice through tough sod, chop up small roots, and penetrate compacted soil that may not have been tilled for decades. This is where those notched edges and the sheer weight of the implement really shine.

After we complete our brush management services, plow discs are invaluable for the next stage of soil preparation. They are used to incorporate the remaining organic matter from mulching into the soil, which accelerates decomposition, improves soil health, and reduces the risk of nitrogen tie-up. This step is what truly transforms cleared land into a productive agricultural field or a pristine landscape.

For food plots, compact disc systems designed for smaller tractors or even ATVs provide the perfect solution. They can efficiently prepare smaller, often remote, areas without the cost and soil compaction of larger equipment, making them ideal for wildlife management projects where precision is key.

The true beauty of plow discs lies in their versatility in challenging conditions. They work effectively in rocky and rooted areas where other implements would snag and break, and they handle hard, dry, trashy conditions where traditional plows would have scouring problems. This inherent adaptability makes them an absolutely essential part of our comprehensive land management toolkit.

Key Features to Consider Before You Buy a Plow Disc

Choosing the right plow disc isn’t as simple as picking the cheapest option or the biggest one you can find at the farm supply store. After years of working with these tools at BrushTamer, and seeing the consequences of poor choices, I’ve learned that the devil is truly in the details. The wrong choice can lead to frustration, damaged equipment, poorly prepared land, and wasted money.

Material Matters: The Unyielding Strength of Boron Steel

When I first started in land management, I made the classic mistake of buying cheaper carbon steel discs to save a few dollars upfront. It was a costly lesson. They wore down faster than a pencil eraser in a math class, chipped on the first rock, and I ended up spending more on replacements and downtime than if I’d just bought quality from the start.

Boron steel is what separates professional-grade tools from the weekend warrior variety. This isn’t just marketing hype; it’s material science. Boron, when added to steel in small amounts and then properly heat-treated, creates an alloy with exceptional hardness and wear resistance. A typical boron steel disc blade might have a Rockwell hardness of 48-52 HRC, allowing it to hold a sharp edge for much longer. More importantly, it provides flexibility. When you’re cutting through rocky soil or hitting hidden roots after our Stump Grinding and Removal work, that engineered flex prevents the catastrophic shattering I’ve seen with brittle, cheaper materials.

Standard carbon steel might look attractive on the invoice with its lower upfront cost, but it’s a false economy. It’s like buying a sports car with bicycle tires. It’ll work for light, occasional use in soft, rock-free soil, but for the demanding conditions we face daily across Indiana, Michigan, and Ohio, you’ll be replacing blades far more often than you’d like. The downtime and replacement costs will quickly eclipse any initial savings.

Size, Thickness, and Compatibility Specifications

Here’s where you match the tool to the task and the tractor. The physical specifications of your plow disc are critical for performance, durability, and even safety.

Disc diameter typically ranges from 16 to 28 inches, and bigger isn’t always better. Larger diameters (24-28 inches) provide deeper cutting action and are better at rolling over obstacles and handling heavy residue. They are essential when we’re preparing land after major clearing operations. A 26-inch blade will slice through compacted soil that a smaller 20-inch disc would just skim over. However, larger discs require significantly more horsepower to pull and more weight to penetrate properly. Smaller discs (16-22 inches) are better for secondary tillage, creating a finer finish, and are suitable for lower-horsepower tractors.

Blade thickness, measured in gauge or millimeters, is where durability lives. A heavy-duty 6 gauge blade (about 5mm thick) will shrug off impacts that would bend or warp a thinner 9 gauge (3.8mm) disc. For the rocky conditions we often encounter, especially after Forestry Mulching, that extra thickness means the difference between finishing the job and calling it a day for repairs. The weight of thicker blades also aids in penetration in hard ground.

Don’t forget about the supporting cast: bearings and mounting hardware. The best blade in the world is useless if the bearing fails. Look for heavy-duty, sealed, regreaseable bearings that can handle high shock loads. Center hole compatibility is another crucial detail. I’ve seen too many people buy the perfect disc online only to find it won’t fit their equipment. Know your bolt pattern: is it a square hole on a square axle, or a round hole with a specific bolt circle (e.g., 4 bolts on a 5-inch circle)? Measure twice, buy once.

Price and Performance Factors in Different Soils

Performance isn’t just about the plow disc itself; it’s about the dynamic interaction between the steel and the soil. In our work across the Midwest, we see it all, and each soil type presents a unique challenge.

Clay soil is a formidable opponent. When dry, it’s like trying to till concrete; when wet, it’s a sticky, smearing mess. For clay, you need heavy discs with aggressive notches to break through compaction. However, you must avoid working it when it’s too wet, as the discs can smear the soil, creating a plow pan that’s impermeable to water and roots.

Sandy soil might seem easy, but it’s highly abrasive. Those fine quartz particles act like sandpaper, rapidly wearing down inferior steel blades. While it’s easy to till, it’s also easy to over-work, which can destroy its fragile structure and lead to wind and water erosion. Boron steel’s hardness is a major advantage here.

Rocky soil is where boron steel truly proves its worth. We’ve seen standard steel blades chip, crack, and even shatter when they hit unexpected glacial till stones common in our region. Disc plows are particularly well-suited for these conditions because they are designed to roll up and over obstacles that would stop a rigid-tine implement cold.

Loam, a balanced mix of sand, silt, and clay, is the ideal soil. It’s easy to work and forgiving, but even here, the right disc choice matters for creating the perfect seedbed and managing residue effectively.

Moisture levels are the great variable that can make or break your operation on any soil type. Too wet, and you’ll cause compaction and smearing. Too dry, and you’ll struggle with penetration, create massive dust clouds, and burn excessive fuel. The ideal is when the soil is moist enough to crumble in your hand but not form a sticky ball.

| Disc Type | Material | Ideal Size (Diameter) | Best Use |

|---|---|---|---|

| Smooth | Boron Steel | 16-22 inches | Secondary tillage, fine seedbed preparation, light residue, sandy/loam soils |

| Notched | Boron Steel | 22-28 inches | Primary tillage, heavy residue, hard ground, breaking new ground, clay/stony areas |

| Tandem | Boron Steel | Varies by width | Primary or secondary tillage, balancing forces, uniform finish, large fields |

| Offset | Boron Steel | Varies by width | Heavy-duty primary tillage, roots, stumps, land clearing, extreme conditions |

The bottom line? A plow disc is a long-term investment. Invest in quality boron steel blades that are correctly sized for your tractor and matched to your specific soil conditions and land management goals. Your future self—and your wallet—will thank you.

How a Plow Disc Transforms Your Land

The real magic happens when a plow disc hits the ground. It’s a moment of change. It’s not just about cutting through soil – it’s about fundamentally re-engineering the topsoil to open up your land’s potential. After years of watching these tools work their magic across the diverse landscapes of the Midwest, I can tell you that the difference between untreated and properly disced land is as stark as night and day.

The Process of Soil Preparation: A Symphony of Actions

When a plow disc rolls across your land, it’s performing multiple, synergistic jobs at once. Think of it as nature’s ultimate mixer, aerator, and prep cook, all rolled into one efficient and powerful machine.

Breaking clods and improving tilth is often the first challenge. Those stubborn chunks of compacted earth that form after primary plowing or in untilled ground don’t stand a chance against the rolling, cutting action of disc blades. The discs slice through these clods like a hot knife through butter, creating smaller, more manageable soil aggregates. This process, known as improving soil tilth, is essential for creating a friable structure that plant roots can easily penetrate.

Incorporating organic matter is where the disc’s mixing action truly shines. All that valuable crop residue, cover crop biomass, or mulched material from our clearing services needs to be integrated into the soil to release its nutrients. The plow disc acts like a giant soil blender, folding this organic treasure into the topsoil. This brings the material into contact with soil microorganisms, moisture, and oxygen, dramatically accelerating decomposition and turning it into stable humus that feeds your land for seasons to come.

The leveling process happens almost magically as the discs work, especially with a tandem harrow. The front gangs throw soil out, and the rear gangs pull it back in, smoothing out ridges, filling in valleys, and erasing wheel tracks. This isn’t just about aesthetics – a level field ensures uniform planting depth, more efficient and even irrigation, and a smoother ride for all subsequent field operations, which ultimately leads to better harvests.

Creating a uniform seedbed is the ultimate goal of most soil preparation. Seeds are demanding; they need consistent depth, good seed-to-soil contact, and a nurturing environment to germinate effectively. The plow disc creates exactly this environment by pulverizing the surface layer, providing a firm base for moisture retention with a loose covering for easy emergence.

The benefits go much deeper than what you can see on the surface. Soil aeration improves dramatically as the discs break up compacted layers, allowing for critical gas exchange. This process lets oxygen penetrate the root zone, which is vital for root respiration, while allowing harmful carbon dioxide to escape. This fosters a healthy environment for beneficial aerobic microorganisms.

Water infiltration gets a major boost as well. Discing breaks up surface crusting and opens up pathways into the soil profile. Instead of running off hard-packed ground and causing erosion, rainfall and irrigation water can penetrate deep into the soil where it can be stored and used by plants. This is especially important when we’re preparing soil after our Stump Grinding and Removal services, where the ground often needs significant remediation before it’s ready for its next chapter.

The mixing action also ensures better nutrient distribution throughout the root zone, while simultaneously providing excellent weed suppression by uprooting young weeds and burying weed seeds too deep for them to germinate, reducing the need for chemical herbicides.

Benefits in the Most Challenging Conditions

Here’s where plow discs truly earn their reputation as indispensable tools. We’ve tackled some incredibly tough conditions over the years, and these implements consistently deliver when other equipment throws in the towel.

Hardpan breaking is a common and serious problem that stumps many landowners. This rock-hard compacted layer, often called a plow pan, forms when soil is worked at the same depth repeatedly. It creates an almost impermeable barrier that chokes roots and causes water to pool. A heavy-duty offset plow disc, with its significant weight and deep penetration, can punch through this hardpan, shattering the compacted layer and instantly improving drainage and root penetration.

Rocky soil and rooted areas are where disc plows truly shine. I remember a project near the Kettle Moraine in Wisconsin, an area notorious for its glacial rock deposits. A traditional moldboard plow would have been destroyed. Our heavy offset disc, however, rolled right through. The discs sliced through smaller roots and simply rolled over or around rocks that would have stopped a rigid plow dead in its tracks. This ability makes them perfect for working newly cleared land or areas that haven’t been cultivated in generations.

Dry, compacted ground that’s as hard as a sun-baked brick doesn’t intimidate a well-designed plow disc. The combination of the implement’s weight, the sharp edges of boron steel blades, and the proper gang angle allows these tools to penetrate conditions that would cause other implements to just bounce uselessly across the surface. Notched discs are particularly effective in these challenging situations, biting in where smooth discs might slip.

The end result of all this hard work is a profound improvement in soil structure that translates directly into better crop growth and land health. When you address compaction, mix in organic matter, and improve both aeration and water movement, you’re creating a resilient, thriving ecosystem beneath the surface. Root systems develop more fully, nutrient uptake improves, and you end up with healthier, more productive land that is more resistant to drought and stress.

From our perspective at BrushTamer, witnessing this change is what makes our work so satisfying. We take overgrown, challenging, and underused terrain and turn it into productive, valuable land that our clients across Indiana, Michigan, Illinois, Ohio, and Wisconsin can use and enjoy for years to come.

Frequently Asked Questions about Plow Discs

Over the years, we’ve fielded countless questions about plow discs from property owners all across the Midwest. Whether you’re a seasoned farmer with thousands of acres or a landowner just getting started with a few acres for a food plot, these are the questions that come up time and again. Here are my straightforward answers based on decades of in-the-field experience.

How do I maintain my plow discs?

Proper maintenance is the key to longevity and performance. A well-maintained disc harrow will serve you for decades; a neglected one will cause constant headaches. Here’s my checklist:

- Regular Inspection: Before every use, do a walk-around. Look for loose bolts, especially on the gangs and bearing hangers. Check tire pressure on wheeled units. After each use, take a closer look at the cutting edges for significant chips or cracks and inspect the bearings for any wobble or excessive heat.

- Cleaning After Use: This isn’t just about looking good. Caked-on soil, especially wet clay, can trap moisture and accelerate rust. It can also add significant weight and throw off the balance of the implement. More importantly, it can transport soil-borne diseases and invasive weed seeds from one field to another. A quick pressure wash is a great investment in biosecurity.

- Proper Storage: If possible, keep your equipment under cover. Rain, snow, and sun are tough on metal, rubber, and hydraulic components. Storing it out of the elements can add years to your equipment’s life. If stored outside, try to park it on boards to keep the discs out of the dirt.

- Checking for Cracks: Stress fractures are the enemy. Pay close attention to the areas around the mounting holes and the main frame welds. A small crack can quickly become a catastrophic failure under load. Catching it early can mean a simple repair instead of a total loss.

- Bearing Lubrication: This is non-negotiable. Follow the manufacturer’s recommendations for greasing the bearings. Some are sealed for life, but most heavy-duty implements have grease zerks. A few pumps of grease push out dirt and moisture and are the cheapest insurance you can buy against bearing failure.

- Sharpening Guidelines: In most soil types, plow discs are self-sharpening. The abrasive action of the soil wears the concave (back) side of the blade faster than the convex (front) side, maintaining a reasonably effective cutting edge. Aggressive sharpening is rarely needed and can reduce the life of the disc. However, if blades become severely rounded from use in non-abrasive soils, replacement is usually a better option than attempting to regrind.

- Replacing Worn Discs: A disc needs to be replaced when it has lost a significant portion of its original diameter—typically 2-3 inches. A worn-down disc loses its concavity, can’t penetrate properly, and won’t move soil effectively. It also reduces the clearance of the whole implement, leading to clogging.

Is discing the same as plowing?

This is a common point of confusion. While both are forms of tillage, they are fundamentally different processes with different outcomes.

- Plowing, typically done with a moldboard plow, is an inversion process. It cuts a slice of soil (a furrow) and completely flips it over, burying virtually all surface residue deep underground. This is very effective for breaking sod and controlling weeds but can leave the soil surface vulnerable to erosion and lead to the formation of a plow pan.

- Discing, on the other hand, is a mixing process. The concave blades of a plow disc cut, lift, and mix the soil without completely inverting it. It’s a less aggressive action that leaves more crop residue on or near the surface. This is a key principle of conservation tillage, as the residue helps protect the soil from wind and water erosion.

They are often complementary processes. In conventional tillage, a field is often plowed in the fall to bury residue, then disced in the spring one or more times to break down clods and create a smooth seedbed. In many modern systems, especially in conservation tillage, discing (or a similar implement like a disc chisel) might be the primary tillage tool used.

How do I set up my disc harrow correctly?

An improperly adjusted disc is inefficient and ineffective. First, ensure it’s level side-to-side and front-to-back when attached to the tractor on level ground. Adjust the tractor’s three-point hitch links as needed. Second, set the gang angle. A more aggressive angle (closer to perpendicular to the direction of travel) moves more dirt but requires more power. A shallower angle is for finishing. A good starting point is around 15-18 degrees. Finally, control your depth with the tractor’s hydraulics or the implement’s transport wheels. The goal is a uniform depth across the entire width of the harrow.

When should I use a plow disc for land clearing?

While our primary approach at BrushTamer involves specialized equipment like forestry mulchers, plow discs are a critical tool in the second phase of land change.

- Breaking New Ground: After we’ve cleared trees and heavy brush, a heavy-duty offset disc is the perfect tool to break through the tough, undisturbed sod layer and network of small roots. It begins the process of converting wild land into workable ground.

- Managing Tough Vegetation: For areas with dense, fibrous root systems like old pastures, the persistent cutting and chopping action of notched discs is invaluable. It tears up the root mat that would resist other methods.

- Preparing Soil After Initial Clearing: This is where plow discs make the biggest difference for our clients. After our Forestry Mulching services turn vegetation into a layer of organic mulch, discing is the essential next step. It incorporates that material into the topsoil, kickstarting the decomposition process and creating a nutrient-rich foundation for whatever comes next—be it crops, pasture, or a new lawn.

The real advantage comes in rocky and rooted areas where other tillage equipment would be destroyed. The rolling action of disc blades lets them steer obstacles that would stop a moldboard plow or chisel plow cold. They are built to handle the unexpected, which is exactly what you need when taming previously uncleared ground.

Conclusion: Choosing the Right Disc for a Perfect Finish

After working with plow discs for years across the varied soils and challenging terrains of the Midwest, I can tell you with certainty that they are far more than just simple pieces of steel. They are foundational tools of change, the critical link between raw land and productive potential. They represent the difference between struggling with your property and watching it flourish into something beautiful and valuable.

Achieving that perfect finish comes down to a few core principles. Task-specific selection is paramount. The heavy, notched offset disc that powers through compacted soil after a land clearing project is the wrong tool for creating a fine seedbed for alfalfa. Conversely, a light tandem harrow with smooth discs won’t make a dent in hard, unbroken ground. You must match the tool to the job.

Your long-term soil health depends on making the right choice. Clay soils demand a different approach than sandy loams, and rocky conditions require the unyielding durability that only high-quality boron steel can provide. We’ve seen too many projects stall and budgets inflate because someone tried to save a few dollars on an implement that wasn’t suited for their specific conditions. An investment in the right equipment pays dividends for years in fuel savings, reduced downtime, and superior results.

When you match the right plow disc to your specific needs, the results speak for themselves. You achieve better land productivity, whether measured in crop yield, pasture quality, or the simple satisfaction of a well-managed property. Proper soil preparation is the first and most important step, and a well-chosen disc system is your primary partner in that effort.

At BrushTamer, we’ve built our reputation on understanding these critical nuances. Our expertise in professional land management isn’t just about running the equipment; it’s about knowing how each step in the process affects the next. We understand when discing fits into the bigger picture—whether it’s the crucial follow-up to our forestry mulching work or the final preparation of ground after stump removal.

For large-scale projects that require professional-grade equipment and deep expertise, specialized Land Clearing Services ensure the job is done safely, efficiently, and correctly the first time. We have the heavy-duty offset discs, powerful tractors, and decades of experience to handle the challenges your smaller plow disc can’t tackle.

Whether you’re a farmer in Indiana, a landowner in Michigan, or managing property anywhere across our service area from Chicago to Toledo, the principles remain the same. Choose your plow disc with care, maintain it diligently, and operate it correctly. It will be one of the most valuable tools in your land management arsenal.

Got questions about which plow disc approach makes the most sense for your land? Or perhaps you need professional help with the heavy clearing work before you can even think about discing? Contact Us. Let’s talk about your goals and how we can help you achieve that perfect finish you’re after.