Introduction: Changing Overgrown Blueberry Orchards

Blueberry bush removal is a task far more complex than most property owners anticipate. An aging or unproductive blueberry orchard represents a significant challenge, tying up valuable land that could be repurposed for new crops, development, or ecological restoration. The problem lies not in the visible canes and leaves, but in the dense, stubborn root systems hidden beneath the soil. Removing these bushes completely, without causing long-term damage to the soil’s health and structure, requires a level of specialized equipment and expertise that goes well beyond typical land-clearing methods.

When we first started clearing blueberry orchards, we found that blueberry bushes are deceptively difficult to remove. With planting densities often exceeding 1,000 plants per acre, each bush develops a resilient, fibrous root system that intertwines with its neighbors, creating a continuous, subterranean mat. Traditional approaches that rely on pulling, digging, or burning often prove to be prohibitively expensive, labor-intensive, and ultimately incomplete, leaving behind root fragments that lead to persistent regrowth.

Property owners throughout agricultural regions face this common dilemma when looking to transition their land. The core question remains the same: How do you efficiently and cost-effectively remove thousands of mature blueberry bushes without destroying the very soil you depend on?

The modern answer lies in a sophisticated reintegration process. This innovative technique involves grinding the entire plant—from the tips of the canes down to the deepest roots—directly into the soil. This approach not only eliminates the problem of waste disposal but also transforms the removal debris into valuable organic matter, enriching the soil and preparing it for its next use in a fraction of the time. I am Leon Miller, owner of BrushTamer, and I have dedicated my work to perfecting blueberry bush removal techniques for commercial orchards. Our team utilizes highly modified forestry mulching equipment, specifically engineered to tackle the unique challenges of high-density blueberry plantings and turn problematic fields into productive assets.

Why Blueberry Bush Removal Demands Professional Expertise

Removing a single backyard blueberry bush might seem straightforward, but scaling that task to a commercial orchard reveals a host of complexities that demand professional intervention. The reality of large-scale blueberry bush removal is a battle fought below the surface, against a biological structure perfected for resilience. Through our extensive work on farms and agricultural properties, we have confirmed that these plants present unique botanical and logistical challenges that standard equipment and methods simply cannot overcome.

Blueberries are typically planted in dense rows, often 10 feet apart with bushes spaced every 4 feet, leading to densities of over 1,000 plants per acre. When these bushes have been established for decades, their root systems merge into a single, formidable underground network. Unlike plants with a central taproot that can be easily severed or pulled, Highbush blueberries possess shallow, intensely fibrous root structures. These systems are composed of countless thread-like roots that form a dense mass in the top 12-18 inches of soil, making them incredibly difficult to extract fully and highly adept at regenerating from any fragments left behind.

The Challenge of Plant Density and Root Biology

With over a thousand plants per acre, each bush aggressively competes for resources, leading to the development of tightly interwoven root mats that are exceptionally difficult to penetrate and break apart. Attempting to remove these with general-purpose equipment, like a standard tractor bucket or excavator, is like trying to tear a tightly woven fabric with your bare hands. The equipment often rips out the main crown but leaves behind a significant portion of the root mass. These remaining roots are not just dormant; they are primed for regrowth, and a field thought to be cleared can quickly become re-infested with blueberry shoots, requiring costly and repeated mitigation efforts. Furthermore, the acidic, sandy, or loamy soils ideal for growing blueberries can complicate removal. While loose, these soils allow roots to spread widely, but they offer little resistance, causing the ground to become easily disturbed and compacted by heavy, inappropriate machinery.

How Blueberry Varieties Influence Removal Strategy

Not all blueberry bushes are created equal, and different cultivars present unique challenges that influence the removal strategy. For example, varieties like ‘Bluecrop’ tend to have a more spreading habit with numerous canes, while others like ‘Elliott’ may grow more upright but with thicker, woodier bases. A mature ‘Jersey’ bush can have 15-20 canes emerging from a dense, gnarled crown that is incredibly tough. The age of the plant is also a critical factor; a 30-year-old bush will have a much more formidable crown and root system than a 10-year-old one. These variations mean a one-size-fits-all approach to blueberry bush removal is destined for failure. True professional service requires the ability to assess the specific conditions of the orchard—including cultivar, age, and soil type—and adapt the equipment and technique accordingly. BrushTamer’s experienced operators and specialized machinery allow us to tailor our methods, ensuring complete and efficient reintegration regardless of the specific challenges presented by the orchard.

The Limitations of Outdated Removal Approaches

Before the development of specialized techniques like our reintegration process, property owners were left with a handful of conventional methods for blueberry bush removal. While seemingly logical, these traditional approaches are fraught with inefficiencies, hidden costs, and significant environmental drawbacks that can hinder the land’s future usability for years. Understanding these limitations is key to appreciating the value of a modern, professional solution.

One of the most common methods involves using excavators or bulldozers to dig and pull the bushes from the ground. While this does remove the visible portion of the plant, it is a brutish and imprecise technique. The process invariably leaves behind countless root fragments, which are the primary culprits for future regrowth. For an orchard with over 1,000 plants per acre, this means thousands of potential regrowth points. This method also causes severe soil disruption. Each extraction leaves a large pit that must be backfilled, and the weight of the heavy machinery leads to deep soil compaction, which ruins soil structure, reduces water aeration, and creates an uneven surface that requires extensive and costly grading to correct.

Another outdated method is burning the bushes, either in place or after piling them up. This approach comes with a host of regulatory and environmental problems. Open burning is heavily restricted in many townships across Michigan and Indiana due to air quality concerns and fire risk. Even where permits are obtainable, the process is deeply flawed. Burning destroys all the valuable organic matter and nitrogen stored in the plants, releasing carbon into the atmosphere instead of returning it to the soil. The intense heat can also sterilize the topsoil, killing off the beneficial microbial communities that are essential for soil health.

The Drawbacks of Conventional Clearing

The inefficiencies of conventional clearing extend far beyond the immediate operational challenges. The entire process creates a protracted timeline that keeps valuable agricultural land out of production. The multi-step sequence of digging, piling, hauling, and then attempting to remediate the damaged soil can take weeks or even months. During this time, the property sits idle, representing a significant loss of potential revenue for the owner. The persistent risk of regrowth from root fragments means the job is never truly finished. A field cleared with an excavator often requires follow-up herbicide applications or mechanical tilling for several seasons to manage the returning blueberry shoots, adding more cost and labor to the project.

Hidden Costs and Extended Downtime

The financial implications of these outdated methods are often misunderstood. The initial quote for a bulldozer may seem reasonable, but the hidden costs quickly accumulate. Hauling and disposing of thousands of bulky, root-bound bushes is a major expense, involving significant trucking costs and landfill tipping fees that can run into thousands of dollars per acre. The cost of repairing the soil is another major factor; this can include purchasing and spreading new topsoil, deep ripping to alleviate compaction, and extensive grading to restore a plantable surface. When you combine these direct expenses with the indirect cost of lost revenue from extended downtime, the true price of conventional blueberry bush removal becomes clear. It is an expensive, inefficient, and ultimately unsustainable way to manage a land transition.

The Reintegration Process: BrushTamer’s Modern Solution

Recognizing the profound limitations of traditional blueberry bush removal, BrushTamer pioneered and perfected the reintegration process. This state-of-the-art method is a paradigm shift in land clearing, designed not just to remove the unwanted plants but to actively improve the soil and prepare the property for its next use with unparalleled efficiency and speed. The core philosophy is simple yet transformative: instead of treating the blueberry bushes as waste to be hauled away, we treat them as a resource to be returned to the earth.

The fundamental concept is to grind the entire blueberry bush, from its leaves and canes down through its dense crown and fibrous root system, directly into the soil where it stands. This single-pass operation completely eliminates the need for costly and disruptive hauling while minimizing soil disturbance and compaction. To achieve this, we employ a fleet of powerful, purpose-built forestry mulching equipment, such as our modified Raptor 800. However, standard mulchers are not sufficient for this task. Our machines are outfitted with a suite of specialized attachments, including high-speed flail mulchers for shredding the above-ground biomass and heavy-duty rotovators designed to pulverize woody root crowns and incorporate all the material into the topsoil.

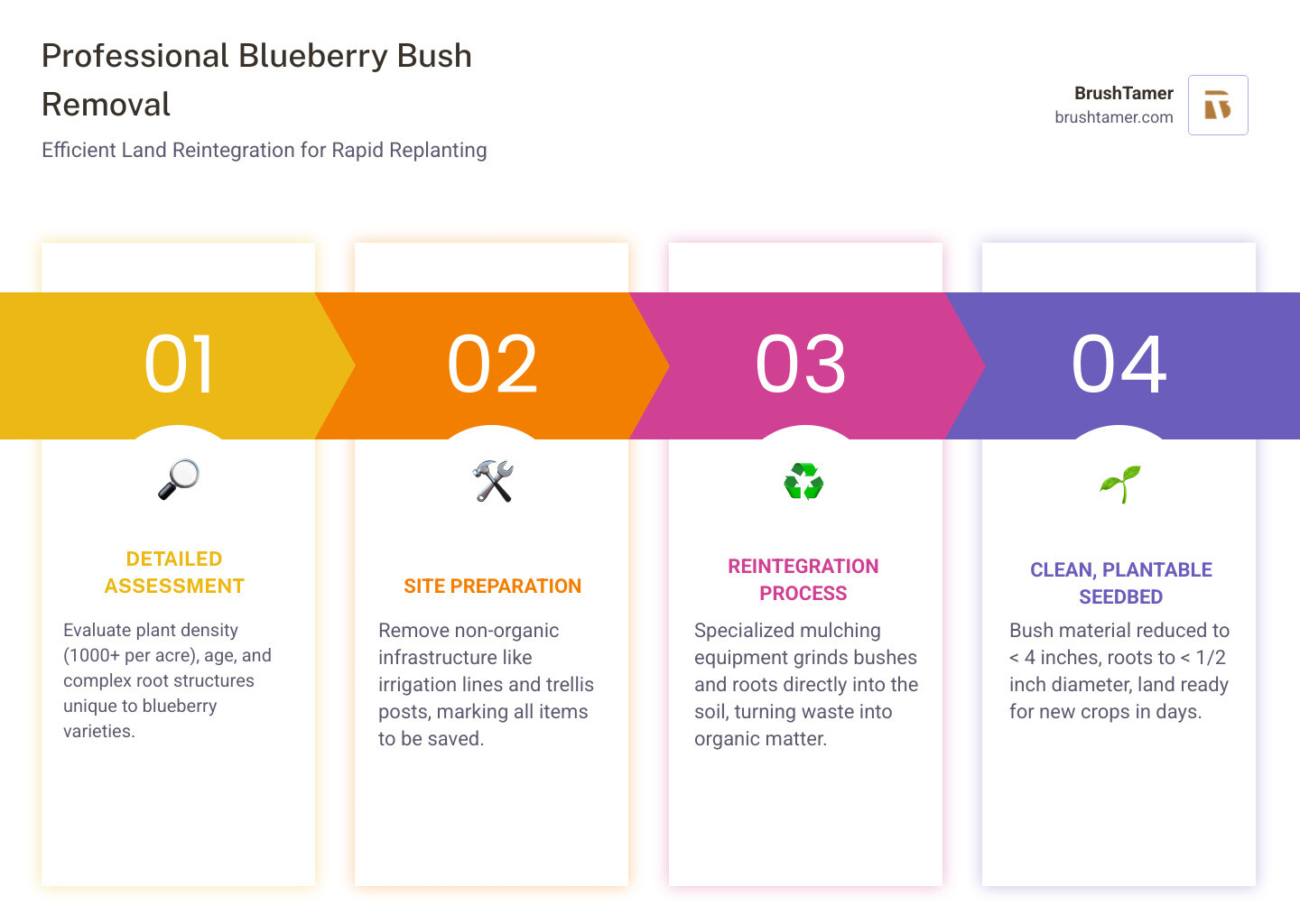

How the Reintegration Process Works in Detail

Our meticulously engineered process systematically deconstructs and incorporates every part of the plant into the soil in a seamless operation:

- Shattering the Above-Ground Bush: The process begins as the mulching head engages the standing bush. The powerful flails or carbide teeth rotate at high speed, shattering the canes and woody stems into small, manageable pieces. The material is consistently reduced to a size of less than 4 inches, creating a layer of coarse mulch on the surface.

- Pulverizing the Root Crown: Next, the operator lowers the specialized head to attack the toughest part of the plant: the dense, woody root crown at the soil line. Our equipment is designed to apply immense torque and force, breaking these stubborn crowns into fragments no larger than a golf ball.

- Grinding and Incorporating the Roots: In the final and most critical step, a specialized rotovator attachment tills the processed material into the top 8-12 inches of soil. This action grinds the remaining fibrous root mat into fine pieces, typically 1/2 inch in diameter or smaller, and thoroughly mixes them with the soil. This ensures there are no viable root fragments left to resprout.

This entire sequence happens on-site, turning a dense orchard into a clean, plantable field without a single truckload of debris leaving the property. The processed plant material immediately begins to decompose, enriching the soil with a massive infusion of organic matter and creating a healthier, more fertile foundation for future growth.

Results You Can Expect from Professional Blueberry Bush Removal

Upon completion of a blueberry bush removal project using the reintegration process, you are left with a transformed landscape that is ready for immediate use. The result is not the rutted, compacted mess left by excavators, but a clean, uniform seedbed. The ground is level and covered with a fine mixture of soil and organic material, perfect for planting new crops, sowing pasture grass, or preparing a site for construction. The speed of this transformation is one of its greatest benefits. It is entirely feasible for a client to finish picking their last harvest on Day 1, have our crew remove irrigation infrastructure on Day 2, watch us perform the complete removal and reintegration on Day 3, and begin replanting their new crop on Day 4.

Preparing Your Property for Professional Removal Services

While our reintegration process for blueberry bush removal is designed to be as self-contained and efficient as possible, proper site preparation is crucial for ensuring a safe, smooth, and maximally effective operation. By taking a few key steps before our crew arrives, you can help us avoid delays, prevent equipment damage, and deliver the best possible results for your property. Think of it as a partnership to ensure a successful land transition.

How to Prepare for the BrushTamer Crew

Before we arrive on-site, please take the following preparatory steps. This checklist is designed to protect both your property and our highly specialized equipment:

- Remove All Non-Organic Infrastructure: This is the most critical step. Go through your rows and remove anything that isn’t a blueberry bush. This includes irrigation drip lines, PVC pipes, metal trellis posts, support wires, anchors, and any other man-made materials. These items can cause thousands of dollars in damage to our mulching heads and bring the project to a halt.

- Mark All Items to Be Saved or Avoided: Clearly identify any features on the property that you want to preserve. Use brightly colored flagging tape or stakes to mark desirable trees, utility boxes, wellheads, septic tank lids, property markers, or sensitive environmental areas. Clear marking prevents accidental damage.

- Address Drip Tube Risers: At the end of each row, it’s common to have vertical PVC risers for the irrigation system. These should be cut off below ground level or dug up and removed entirely. Burying them is also an effective option to ensure our equipment can process the ends of the rows cleanly.

- Ensure Clear Access and Communication: Discuss access routes with us ahead of time. We need to know the best way to get our large equipment onto the property. Also, be prepared to clearly define the exact boundaries of the work area. Open communication about property lines and any potential hazards is essential for a smooth project.

What to Avoid: Common Mistakes That Hinder the Process

Equally important is knowing what not to do. Avoid these common actions that can inadvertently complicate the removal process:

- Do Not Mow or Cut the Plants Before Arrival: It may seem helpful, but mowing the bushes is counterproductive. Our equipment is designed to use the standing plant for leverage, allowing for a cleaner and more controlled grinding process. Mowing creates a field of stumps and debris that is much harder to process uniformly and can result in a less consistent final product.

- Do Not Attempt Partial Removal Yourself: Trying to pull out a few bushes with a chain or a small tractor often does more harm than good. This typically snaps the bush at the crown, leaving the entire root system intact. It also creates uneven ground and hidden obstacles that can be hazardous for our operators and equipment, requiring extra time to correct.

Frequently Asked Questions about Blueberry Orchard Removal

We understand that transitioning an entire orchard is a significant undertaking. Here are answers to some of the most common questions we receive about our professional blueberry bush removal services.

How quickly can I replant my field after the service?

One of the most significant advantages of BrushTamer’s reintegration process is the exceptionally fast turnaround time. Because we process all the material on-site and leave the soil in a plantable condition, your land is often ready for its next use the very next day. Unlike conventional methods that can take weeks or months of clearing, hauling, and soil remediation, our process allows for a nearly seamless transition from one crop to the next, minimizing downtime and lost revenue.

Does the density of my blueberry planting affect the service?

Yes, the density, age, and overall condition of the planting are key factors we assess when planning a project. A typical mature orchard with over 1,000 plants per acre is exactly what our specialized equipment is designed to handle. Higher densities or older plants with thicker crowns may require more time per acre, which is factored into our project scope and timeline. However, high density is not a deterrent; it’s a challenge we are fully equipped to meet efficiently.

What happens to all the plant material?

All of the plant material—every leaf, cane, crown, and root—is “reintegrated” directly into your soil. Our machinery systematically pulverizes the bushes into small pieces (above-ground material less than 4 inches, root crowns golf ball-sized or smaller, and roots to 1/2 inch diameter). This finely ground organic matter is then thoroughly mixed into the topsoil. Instead of being hauled to a landfill, this material becomes a valuable soil amendment, returning nutrients and improving soil structure for whatever you plan to grow next.

Will the ground-up wood chips negatively impact my soil’s nitrogen levels?

This is an excellent question and a common concern in agriculture. When large amounts of high-carbon material (like wood chips) are added to soil, microbes use available soil nitrogen to break it down, a process known as nitrogen immobilization or “tie-up.” However, our reintegration process is specifically designed to mitigate this effect. By grinding the material into very small particles and thoroughly incorporating it into the soil, we maximize the surface area and promote rapid decomposition. The effect on nitrogen is typically minimal and temporary. For highly sensitive crops, a simple soil test after clearing and a small application of starter nitrogen may be recommended, which is a minor and inexpensive step compared to the extensive soil damage from other methods.

Is this process suitable for certified organic farms?

Absolutely. Our reintegration process is purely mechanical. We use no chemicals, herbicides, or contaminants of any kind. The entire operation is based on grinding and incorporating the existing plant matter. In fact, the process is highly beneficial for organic systems as it dramatically increases the organic matter content of the soil, which is a cornerstone of organic farming. It’s a sustainable, eco-friendly method for clearing land while adhering to strict organic standards.

Your Partner for Efficient Land Change

Navigating the complexities of blueberry bush removal requires more than just heavy machinery; it demands specialized knowledge, state-of-the-art equipment, and a deep commitment to sustainable land management. BrushTamer embodies this unique combination, serving as the premier partner for agricultural producers, commercial growers, and land developers who need to transform their property efficiently and effectively. Our proven reintegration process is the modern answer to the age-old problem of clearing overgrown or unproductive orchards.

We deliver fast, reliable, and cost-effective results, whether you are reclaiming long-neglected land, preparing a field for new and diverse crops, or transitioning property for a different use. By choosing BrushTamer, you are choosing a method that minimizes downtime, completely eliminates debris hauling and disposal costs, and actively enriches your soil for its next chapter. We turn a liability into an asset, leaving you with a clean, healthy, and productive landscape.

For a land-clearing solution that respects your land, your time, and your bottom line, choose BrushTamer. We are proud to serve communities throughout Lower Michigan and Northern Indiana, including:

- Northern Indiana: South Bend, Elkhart, Mishawaka, Goshen, La Porte, Valparaiso, Crown Point, Merrillville, Fort Wayne, Warsaw, and surrounding areas.

- Lower Michigan: Kalamazoo, Battle Creek, Grand Rapids, Paw Paw, Niles, Benton Harbor, St. Joseph, Dowagiac, and surrounding areas.

Learn more about how we can help you with your land transition by visiting our Blueberry Orchard Removal Services page or contacting us for a consultation.